Are you looking for help with a metal stamping project?

Toolitem is your expert partner for custom metal stamping. We specialize in high-speed precision, deep draw, progressive die, and compound die stamping, delivering quality parts for diverse industries. Let us bring your project to life.

Our team holds several years of experience in metal stamping and has served customers in various industries. Please keep contacting to learn more about our services.

How to Custom Metal Stamping?

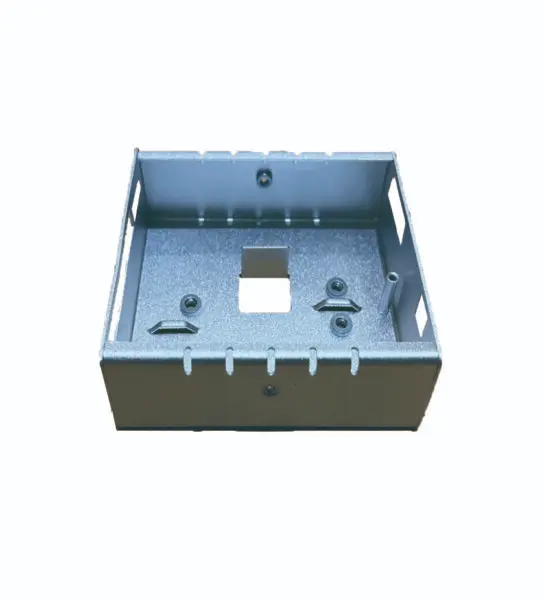

Custom metal stamping transforms sheets, strips, or coils of metal into precise components. Using a stamping press and custom dies, we apply controlled, high pressure to the material. This force shapes the metal through deformation or cutting, resulting in durable parts made to your exact design requirements.

Why Choose Toolitem for Your Custom Metal Stampings?

Your Trusted Metal Stamping Partner for 20 Years

We are a global expert in metal stamping, backed by a team of dedicated design engineers and mold technicians committed to excellence.

Why Partner With Us?

- Deep Expertise: Nearly two decades of engineering and mold technology experience.

- Guaranteed Quality: Rigorous process control ensures reliable and consistent results.

- Supply Chain Stability: Flexible, reliable production and one-stop services secure your supply chain efficiency.

Our mission is to simplify and strengthen your custom metal stamping process, delivering the reliability you need to gain a competitive advantage. We support this goal with specialized expertise across a comprehensive range of services:

Progressive Stamping: For both high-volume and low-volume production runs.

Secondary Stamping: Dedicated low-volume operations for added forming or features.

In-Die Tapping: Integrated thread creation within the stamping process for efficiency.

Secondary/Assembly Tapping: Post-stamping threading and fastening assembly.

Forming & Machining: Complementary precision forming and machining services.

Adding More Value to Your project

To enhance the durability and extend the service life of your custom metal stamping components, we offer the following value-added services:

| 1. Black Oxide finish | 2. Heat Treating | 3. Deburring | 4. Magnetic Particle Inspection |

| 5. Passivation | 6. Dry Film Coating | 7. Powder Coating | 8. Laser Marking |

| 9. Bright Anneal | 10. Plating | 11. Burnishing | 12. Electro-Chemical Etching |

These value-added services enhance your product by imparting resistance to abrasion, corrosion, and rust. They also improve surface integrity by minimizing subsurface imperfections, resulting in a smooth, uniform finish. Additionally, we can permanently engrave barcodes or text for part traceability and identification.

Click right to get in touch with our team or request a quote?